Engineered Lumber by SKILLICORN Technologies

How 100% Engineered Lumber creates synergies and adds value to advanced, innovative Lumber products

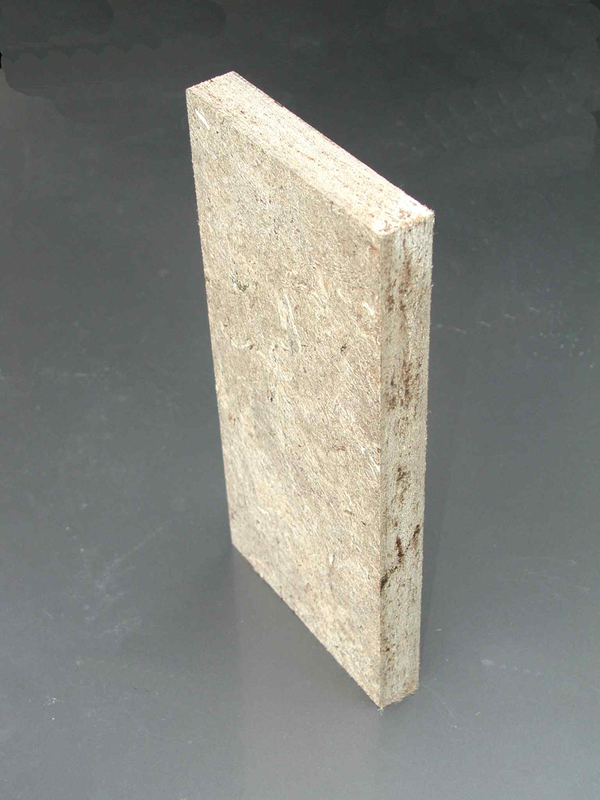

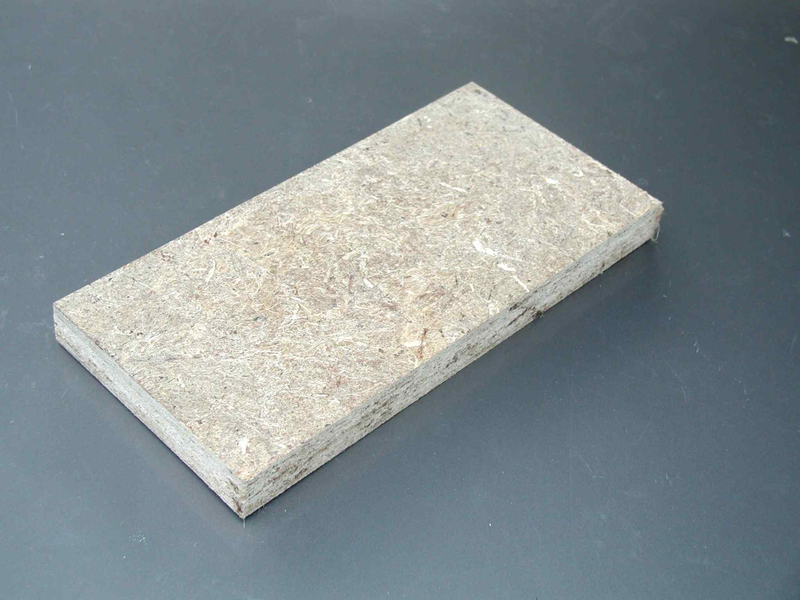

Most engineered lumbers such as OSB, plywoods and LVLs use common lumber such as pine and lack truly superior strength. These lumbers also use inexpensive petroleum-based binders and resins that are increasingly recognized to be toxic. STL is reinventing engineered lumber. No wood is involved. The underlying material comprises Arundo donax, which is the fastest growing lignocellulosic material in the world (150 tonnes can be grown per hectare per year, versus only 15 tonnes or so per hectare per year for intensively-grown pine) and dramatically stronger (tensile strength) than pine or fir. These are reinforced with bast fibers of kenaf and bound with 100% natural Lemnaceae-derived copolymers – themselves engineered specifically to the circumstance. STL Lemnaceae-bound bast-reinforced Arundo donax engineered lumbers can effect virtually any shape or form because of the high flexibility of Arundo donax and the absolute flexibility of kenaf bast fibers. STL’s internal application for its engineered lumbers is kits for quick assembly of dodecahedron geodesic dome structures and their interiors – industrial, agribusiness and households. An STL engineered strut measuring 2” x 2,” for instance, is much lighter and dramatically stronger than a 2” x 6” pine strut that would normally be applied to the same purpose.

With forests being cleared for lumber and paper applications, simply planting Arundo donax and kenaf, and employing them in the manufacture of highly optimized STL engineered lumbers can have a massively beneficial effect. With a 3 to 5 fold strength-for-weight advantage over common lumbers, and a 10-fold advantage as to productivity, one hectare of STL engineered lumber “plantation” can compensate for between 60 and 100 acres of virgin forest and around 50 acres of intensively-grown eucalyptus or pine plantations. The benefits contributed to the global battle to mitigate climate change are commensurate.

With forests being cleared for lumber and paper applications, simply planting Arundo donax and kenaf, and employing them in the manufacture of highly optimized STL engineered lumbers can have a massively beneficial effect. With a 3 to 5 fold strength-for-weight advantage over common lumbers, and a 10-fold advantage as to productivity, one hectare of STL engineered lumber “plantation” can compensate for between 60 and 100 acres of virgin forest and around 50 acres of intensively-grown eucalyptus or pine plantations. The benefits contributed to the global battle to mitigate climate change are commensurate.

BENEFITS OF STL

We MAKE and DELIVER SUPERIOR BI0-PLASTICS & SUPERIOR ENGINEERED LUMBERS-- where it is otherwise unavailable LOCALLY, IN YOUR NEIGHBORHOOD -- and we do it less expensively and at a better quality and more reliably than anyone else in the world -- AND . . We also use up the CO2 we produce, and we have a residual of energy and pure water, which we use efficiently.

WHY? Because we are THE producers of duckweeds, Arundo donax, kenaf seeds and kenaf -- and use the world's most advanced production technologies such as: groundwater cooled and heated pneumatic greenhouses; advanced buried drip fertigation; advanced mass tissue-culture and propagule development and transplantation and rhizome crop maintenance.

WHY? Because we are THE producers of duckweeds, Arundo donax, kenaf seeds and kenaf -- and use the world's most advanced production technologies such as: groundwater cooled and heated pneumatic greenhouses; advanced buried drip fertigation; advanced mass tissue-culture and propagule development and transplantation and rhizome crop maintenance.